- Nuovo

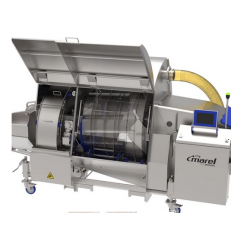

Mobile-Salting-Elevator MSE-480 and MSE-280

Much more than salt for the nut

Descrizione

With our mobile salting equipment nuts and kernels will be salted, spiced, flavored or dry coated carefully and continuously. Salting and coating take place while vertical conveying of the product. A polished stainless steel spiral reduces the adhesion of the product on its surface. Good mixing causes an even appearance and a pleasant taste distribution on the product. The mobile unit can be used independently before or after roasting. Parameters such as salt and oil quantity, angle of the spiral as well as spiral speed can be adjusted precisely by means of a modern control.

The capacity of our machines is up to 2,500 kg per hour / 5,500 lb per hour (pistachios, almonds, cashew nuts, and others). Thanks to its modular design, they are small, compact, and extremely flexible. They are easy to use and require only a 32 A CEE socket and a ¾" water connection for the operation. Our salting - and coating - machines have a built-in cleaning-in-place system for easy cleaning. All parts that get wet are made of stainless steel or with an FDA approval.

In addition to the basic model, we offer an expansion module, with which e.g. pistachios with shell can be salted before roasting. With a second expansion module in conjunction with first module, almonds, macadamia nuts and other specialties can be salted before roasting. Individually inserted, it serves the oil and salt or spice for example for cashew nut after roasting.

Since more than 25 years the company Nolte produces and sells continuous belt dryers and roasters (“Nutmaster”) for thermal treatment of food and other production.

Due to its extensive experience, careful construction and high quality manufacturing our systems are reliable and innovative. Our systems are in use worldwide and provide our customers with a reliable production at the highest level. As complement we developed the mobile salting machine MSE-480 and her smaller sister, the MSE-280.

The mobile salting machine MSE-480 is a system for continuous salting with brine and for dry salting or coating of nuts and seeds before and after roasting with simultaneous vertical product transport.

Features and Performance

• Capacity from 750 kg / h to 2,500 kg / h (pistachios, almonds, cashews)

• Individual planning and construction according to customer specifications

• Only a 32 A CEE socket and ¾ " water connection necessary

• Continuous and gentle salting of nuts and kernels

• Very good mixing for an even appearance of the product

• Simultaneous salting and vertical conveying of the product

• Flexible use of installation due to modular construction

• System can be moved and thus before or after roasting usable

• Compact design for a small footprint

• Integrated Cleaning-in-place feature for easy cleaning

• Polished stainless steel spiral for less product adhesion

• Good accessibility through side panels with quick connectors

• Large window for product monitoring during operation (Optional)

• Electrical lifting device for lifting and lowering of the spiral conveyor

• All parts that could get wet are made of stainless steel or FDA approved

• The system is easy to use and intrinsically safe

• All parameters can be adjusted e.g. salt and oil quantity, scroll speed

• Modern Siemens control with large control panel

Modular design (MSE-480.400.03)

Basic unit: Spiral Conveyor with base frame, pumps, solenoid valves, sensors, CIP cleaning device and the lifting device including control which is fitted directly on the base or a separate frame.

Additional Module 1: Mixing station with frequency-controlled agitator, sensors for level and salinity measurements and all necessary connections. The station is connected by hoses and an industrial standard connector with the controller and allows the production of brine or gum arabic solution. This module allows e.g. the salting of pistachio in shell before roasting.

Additional module 2: Dry salt application with frequency-controlled dosing unit, sensors for level and salt flow control, vibration drive to avoid lumps and a salt container made of stainless steel. The dry salt applicator is also connected with an industrial plug to the controller and allows the exact dosing of dry salt. This module works together with module 1 for the salting of almonds, macadamias and other specialties before roasting. And solely, the oiling and salting of e.g. Cashews after roasting.

17 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Continuous drum coating machine for adding spices and flavors AD

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT